Transforming orthotics with 3D printing

Orthoses, often referred to as orthotics, are traditionally passive devices worn by people to support an injured or weak body part.

The ambitious, yet simple vision of this advancement in AFOs is about the look on a patient’s face – the moment they walk comfortably out of the treatment room with improved mobility and confidence. Clinicians happy in the pursuit of good fit and prompt, effective treatment. Custom fit every time, affordably and with less downtime.

By Andrew Hanson and Scott Rader, Stratasys 25 February 2016

While many people will be familiar with the use of temporary braces after an injury, a significant proportion of orthotics are used for long term care to address multiple conditions. These conditions include foot drop from muscle weakness or neuromotor issues due to stroke, multiple sclerosis, cerebral palsy, hypotonia, as well as other nerve and gait conditions. Orthoses also assist in stabilizing painful osteoarthritic joints and correcting joint deformity.

With aging populations worldwide, the number of people wearing orthoses has grown significantly in the past three decades. Projections indicate that 7.3 million people in the United States will use orthoses to combat the effects of paralysis, deformity or orthopedic impairments by 2020. While demand increases, manufacturing techniques have not changed dramatically in decades.

The University of Michigan has partnered with Altair Engineering and Stratasys to form the CYBER team. And the CYBER team was recently selected and funded by America Makes (the National Additive Manufacturing Innovation Institute) to work together on a solution that will leverage 3D printing and Industry 4.0 to transform the design, comfort, utility and customization of Ankle Foot Orthotics (AFO). This solution will incorporate digital design, additive manufacturing through 3D printing, and leverage industry leaders at the University of Michigan Orthotics and Prosthetics Center to deliver on emerging Industry 4.0 trends.

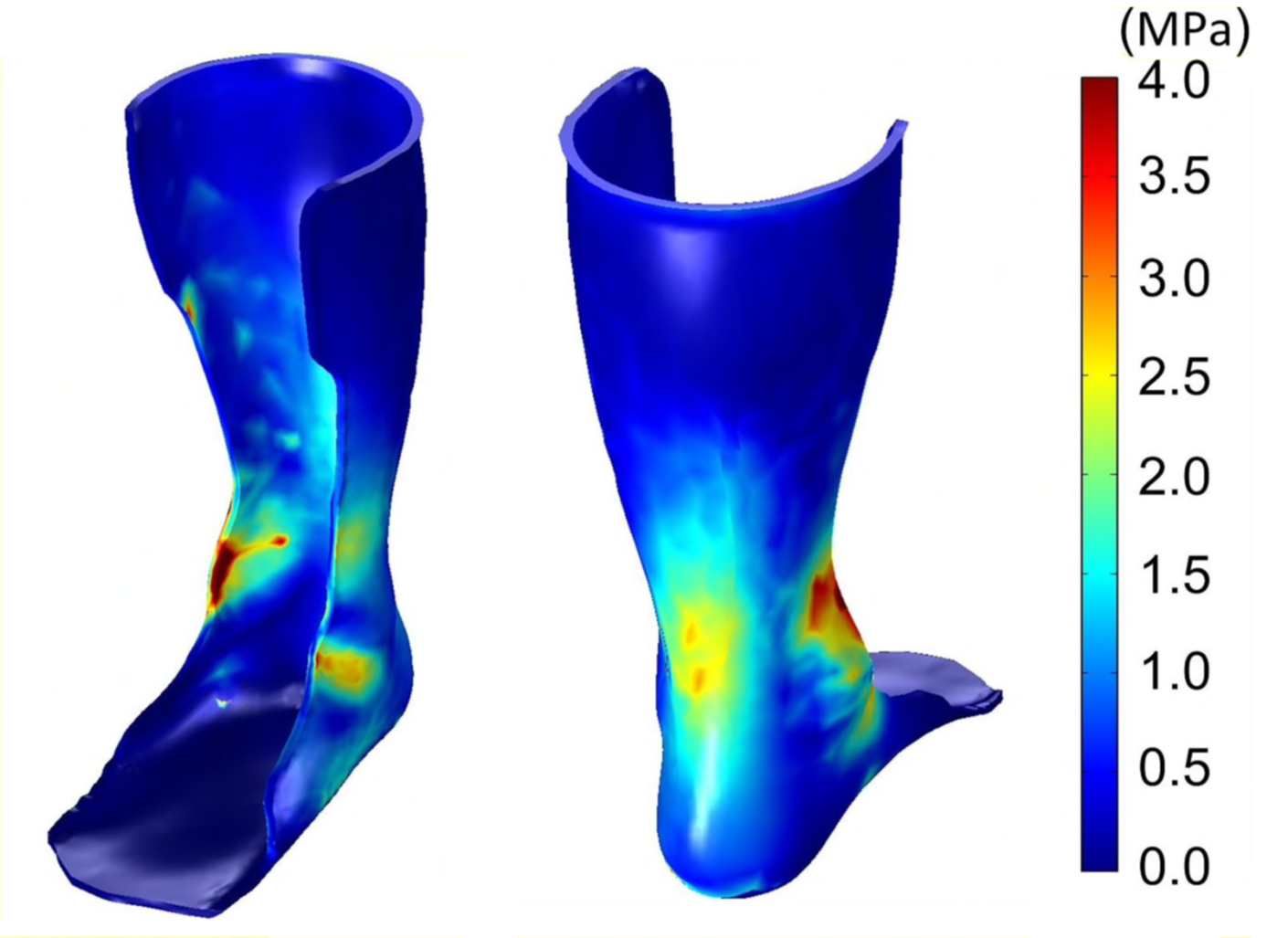

In order to accomplish this, the CYBER team will create the digital workflow for additive manufacturing design – connecting the digital thread for clinicians, engineers and designers, incorporating fused deposition modeling FDM® fabrication methods and Altair® OptiStruct® analysis software for the production of customized ankle-foot orthoses (AFO).

| Ankle foot orthotic manufacturing: The CYBER solution |

The CYBER team has come together to directly address these pain points affecting patients and care-givers, while accelerating and reducing the cost of delivery of optimized ankle foot orthoses.

This future cloud-based cyber physical system will allow clinicians to create Ankle Foot Orthoses by utilizing an online portal, combining clinician expertise with automated tools to create the patient’s prescription. The engineered cyber-physical system provides the seamless integration of the cloud based algorithms with the physical component manufacture to optimize overall part geometry and its corresponding tool-paths. The advantages of an additive manufacturing solution for Ankle-Foot Orthoses are compelling:

- Reduce the long delivery time – Typical delivery time is 2-4 weeks for AFOs. The team plans to reduce this delivery time to 1 day through the cyber-physical system.

- Enhance the level of accuracy – Plaster shrinks after drying so plaster molds do not accurately duplicate the patient’s ankle and foot shape without iterations or the skill of a certified orthotist. The team plans to utilize precise, 3-dimensional scanning to provide exact dimensions for instant, exact AFO accuracy while utilizing design for additive manufacturing compensation techniques.

- Eliminate multiple visits – This is taxing for users and caregivers, and drives cost.

- Enhance design freedom – Shapes of AFOs are limited by current manufacturing practices, which cannot fabricate orthoses that require more intricate, functional designs.

The team plans to improve the manufacturing process to provide single-visit patient care.

| Finite element modeling of the human foot and footwear, PDF |

The team plans on allowing computational model and tool path based optimization to drive future AFO design, while encouraging clinician input to provide personalized care. The average age of a lower extremity orthotic wearer is 70 years old; light-weighting and ease of use are paramount in this project.

Of course, no one person can properly execute all of the required knowledge to operate the current workflow needed to achieve this cyber-physical system. Engineers, such as those at Stratasys and Altair, along with clinicians at orthotics & prosthetics centers, are the only people knowledgeable enough to execute each specific task.

Between multiple file types, the creation of structural and tool path optimization files, design for additive manufacturing considerations, and orthotic best practices, the amount of manual computational analysis is daunting. Adding to the expertise needed, the current additive manufacturing workflow has drawbacks

- Machine throughput – The current additive manufacturing technologies do not provide high enough throughput to enable the one-day visit for ankle-foot orthotics. A new design methodology is required to increase throughput and lower material usage, while maintaining structural integrity and functionality.

- Multiple materials – Both stiff material for structural functionality and a soft material for comfortable interfacing are needed in one custom orthosis.

- Lack of clinical interface and system integration – There is no software system that can seamlessly process all the data from the patient’s 3D scan geometry to shape of the orthosis, and to the printable command file.

| Military veterans may be the first to benefit |

Aligning with the team’s commitment to military veterans and their families, the US Veterans Administration (VA) in Ann Arbor, Michigan will be one of the first partners to receive this solution with the goal of deploying it to VA Orthotics & Prosthetics locations nationwide once testing is complete. From 2005 to 2009, the annual VA spending on O&P related items has increased almost 80%, from $907M to $1.6B. About 1.5 million orthoses were provided to veterans in 2009.

These numbers are continually growing as the number of enrollments in VA Healthcare increases with the aging of the overall population. As concluded in the American Orthotic Prosthetic Association (AOPA) study, the savings for Medicare could be $1.3B per year by 2020 after full deployment of this solution to the VA network.

This project is scheduled to complete its proof-of-concept in 2017.

Source Stratasys via 3ders.org

| References |

Embracing additive manufacture: implications for foot and ankle orthosis design, Telfer S, Pallari J, Munguia J, Dalgarno K, McGeough M, Woodburn J. BMC Musculoskelet Disord. 2012 May 29;13:84. doi: 10.1186/1471-2474-13-84. Full text

Patient specific ankle-foot orthoses using rapid prototyping, Mavroidis C, Ranky RG, Sivak ML, Patritti BL, DiPisa J, Caddle A, Gilhooly K, Govoni L, Sivak S, Lancia M, Drillio R, Bonato P. J Neuroeng Rehabil. 2011 Jan 12;8:1. doi: 10.1186/1743-0003-8-1. Full text

Additive Manufacturing of Custom Orthoses and Prostheses – A Review, Yu-an Jin, Jeff Plotta, Roland Chena, Jeffrey Wensmanc, Albert Shiha. Procedia CIRP Volume 36, 2015, Pages 199–204. CIRP 25th Design Conference Innovative Product Creation. doi: 10.1016/j.procir.2015.02.125.

Also see

☞ Patient specific ankle-foot orthoses using rapid prototyping

Perfect fit 3D printed leg brace

Med-tech startup run by Johns Hopkins students aims to build better orthotics Johns Hopkins University Hub

Better orthotics for those that matter Fusiform Medical Devices

torc2’s clever design solution for the NHS The Telegraph

Lightweight Leg Brace Cost-Effectively Customized for Perfect Fit with Stratasys 3D Printing the Startasys blog

Stratasys & Michigan University join forces in CYBER to revolutionize orthotics with 3D printing 3ders.org

Industry 4.0: It’s all about information technology this time ZDNet