Embroidering electronics into the next generation of ‘smart’ fabrics

Is an archaic sewing skill a key to connected, sensing, communicating fabrics of the future?

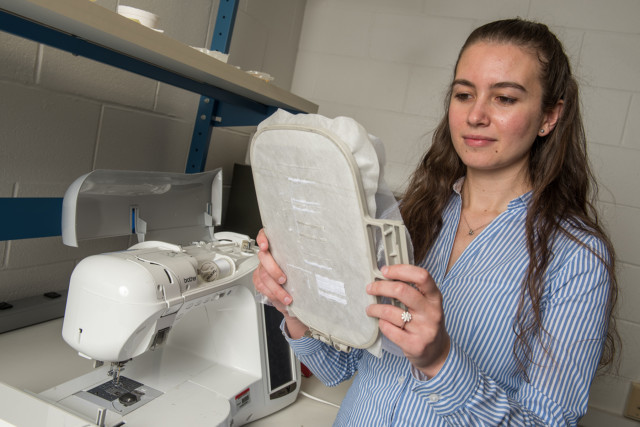

Ohio State researchers in the Electro Science Lab are developing embroidered antennas and circuits with 0.1 mm precision—the perfect size to integrate electronic components such as sensors and computer memory devices into clothing. Jo McCulty, The Ohio State University

Asimina Kiourti, Ohio State University, The Conversation March 12, 2018

Archaeology reveals that humans started wearing clothes some 170,000 years ago, very close to the second-to-last ice age. Even now, though, most modern humans wear clothes that are only barely different from those earliest garments. But that’s about to change as flexible electronics are increasingly woven into what are being called “smart fabrics.”

Many of these are already available for purchase, such as leggings that provide gentle vibrations for easier yoga, T-shirts that track player performance and sports bras that monitor heart rate. Smart fabrics have potentially promising uses in health care (measuring patients’ heart rate and blood pressure), defense (monitoring soldiers’ health and activity levels), cars (adjusting seat temperatures) to make passengers more comfortable and even smart cities (letting signs communicate with passersby).

Ideally, the electronic components of these garments – sensors, antennas to transmit data and batteries to supply power – will be small, flexible and largely unnoticed by their wearers. That’s true today for sensors, many of which are even machine-washable. But most antennas and batteries are rigid and not waterproof, so they need to be detached from the clothing before washing it.

Asimina Kiourti, Electro Science Lab, The Ohio State University

My work at the ElectroScience Laboratory of the Ohio State University aims to make antennas and power sources that are equally flexible and washable. Specifically, we’re embroidering electronics directly into fabrics using conductive threads, which we call “e-threads.”

An embroidered antenna. ElectroScience Lab, CC BY-ND

| Antenna embroidery |

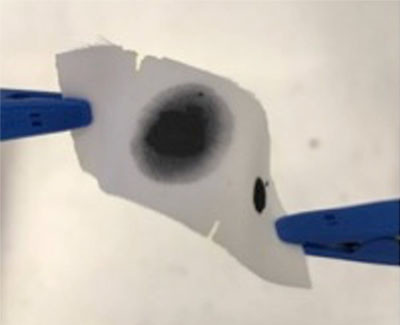

Printed on fabric, metals can generate power. ElectroScience Lab, CC BY-ND

The e-threads we’re working with are bundles of twisted polymer filaments to provide strength, each with a metal-based coating to conduct electricity. The polymer core of each filament is typically made out of Kevlar or Zylon, while the surrounding coating is silver. Tens or even hundreds of these filaments are then twisted together to form a single e-thread that’s usually less than half a millimeter across.

These e-threads can be easily used with common commercial embroidery equipment – the same computer-connected stitching machines that people use every day to put their names on sports jackets and sweatshirts. The embroidered antennas are lightweight and just as good as their rigid copper counterparts, and can be as intricate as state-of-the-art printed circuit boards.

Our e-thread antennas can even be combined with regular threads in more complex designs, like integrating antennas into corporate logos or other designs. We’ve been able to embroider antennas on fabrics as thin as organza and as thick as Kevlar. Once embroidered, the wires can be connected to sensors and batteries by traditional soldering or flexible interconnections that plug components together.

So far, we’ve been able to create smart hats that read deep brain signals for patients with Parkinson’s or epilepsy. We have embroidered T-shirts with antennas that extend the range of Wi-Fi signals to the wearer’s mobile phone. We also made mats and bedsheets that monitor infants’ height to screen for a range of early childhood medical conditions. And we’ve made foldable antennas that measure how much a surface the fabric is on has bent or lifted.

| Moving beyond the antenna |

My lab is also working with other Ohio State researchers, including chemist Anne Co and physician Chandan Sen to make flexible fabric-based miniature power generators.

We use a process much like inkjet printing to place alternating regions of silver and zinc dots on the fabric. When those metals come into contact with sweat, saline or even fluid discharges from wounds, silver acts as the positive electrode and zinc serves as the negative electrode – and electricity flows between them.

The Embroidered Computer is an exploration into using historic gold embroidery materials and knowledge to craft a programmable 8 bit computer. Irene Posch

We have generated small amounts of electricity just by getting the fabric damp – without the need for any additional circuits or components. It’s a fully flexible, washable power source that can connect with other wearable electronics, eliminating the need for conventional batteries.

Both together and individually, these flexible, wearable electronics will transform clothing into connected, sensing, communicating devices that mesh well with the fabric of the interconnected 21st century.

| The Ohio State University: Origami Antennas. Recent Undergraduate Honors Research Scholarship winner, Shreyas Chaudhari, discuss his work at The Ohio State University with Electrical and Computer Engineering Assistant Professor Dr. Asimina Kiourti and Mechanical and Aerospace Engineering Assistant Professor Dr. Ryan Harne. |

| Chaudhari is developing an origami-based tessellated antenna whose operating frequency and radiation pattern can be self-tuned by adjusting the shape of the antenna itself.”The antenna is fabricated using polymer threads, and can be easily integrated into clothing and mechanical structures to provide a non-invasive way to quantify flexion and deformation. The project provides a unique opportunity to incorporate art with electromagnetics, and I am very excited by the potential applications,” he said. |

| Read more about the work of recent scholarship winners. Project made possible from a STEAM factory grant at Ohio State. ECEosu. Youtube Feb 22, 2018 |

| Asimina Kiourti is Assistant Professor of Electrical and Computer Engineering, Ohio State University. |

| Disclosure statement. Asimina Kiourti receives funding from the National Science Foundation, the Defense Health Agency, the STEAM Factory, the Consortium on Electromagnetics and Radio Frequencies, the OSU Discovery Themes, and the OSU Innovation Studio. |

![]() Source The Conversation

Source The Conversation ![]()

| Further reading |

A tailored, electronic textile conformable suit for large-scale spatiotemporal physiological sensing in vivo, Wicaksono I, Tucker CI, Sun T, Guerrero CA, Liu C, Woo WM, Pence EJ, & Dagdeviren C. (2020). npj Flexible Electronics, 4(1), 5. https://doi.org/10.1038/s41528-020-0068-y. Full text

A Wireless Fully Passive Neural Recording Device for Unobtrusive Neuropotential Monitoring, Asimina Kiourti, Cedric WL Lee, Junseok Chae, John L Volakis. IEEE Transactions on Biomedical Engineering Volume 63, Issue 1, Jan. 2016. DOI: 10.1109/TBME.2015.2458583

Fabrication of Textile Antennas and Circuits With 0.1 mm Precision, Asimina Kiourti, Cedric Lee, John L Volakis. IEEE Antennas and Wireless Propagation Letters Volume 15, 20 May 2015. DOI: 10.1109/LAWP.2015.2435257

High-Geometrical-Accuracy Embroidery Process for Textile Antennas With Fine Details, Asimina Kiourti, John L Volakis. IEEE Antennas and Wireless Propagation Letters Volume 14, 15 October 2014. DOI: 10.1109/LAWP.2014.2363556

Embroidered Conductive Fibers on Polymer Composite for Conformal Antennas, Zheyu Wang, Lanlin Zhang, Yakup Bayram. IEEE Transactions on Antennas and Propagation Volume 60, Issue 9, Sept. 2012. DOI: 10.1109/TAP.2012.2207055

A Review of Implantable Patch Antennas for Biomedical Telemetry: Challenges and Solutions , Asimina Kiourti, Konstantina S Nikita. IEEE Antennas and Propagation Volume 54, Isuue 3, 31 August 2012. DOI: 10.1109/MAP.2012.6293992

Superelastic Multimaterial Electronic and Photonic Fibers and Devices via Thermal Drawing, Y Qu, T Nguyen‐Dang, AG Page, W Yan, T Das Gupta, GM Rotaru, RM Rossi, VD Favrod, N Bartolomei, F Sorin, Adv. Mater. 2018, 1707251. https://doi.org/10.1002/adma.201707251

Troubling Innovation: Craft and Computing Across Boundaries, Irene Posch, Ozge Subasi, Daniela K. Rosner, Raune Frankjaer, Amit Zoran, Tania Pérez-Bustos. Proceeding CHI EA ’19 Extended Abstracts of the 2019 CHI Conference on Human Factors in Computing Systems, Paper No. W16. Glasgow, Scotland Uk May 04-09, 2019. ISBN: 978-1-4503-5971-9 doi: 10.1145/3290607.3299010

| An elastic fiber filled with electrodes set to revolutionize smart clothes. EPFL scientists have found a fast and simple way to make super-elastic, multi-material, high-performance fibers. Their fibers have already been used as sensors on robotic fingers and in clothing. This breakthrough method opens the door to new kinds of smart textiles and medical implants. École polytechnique fédérale de Lausanne (EPFL). Youtube May 25, 2018 |

| Electronic Textile Conformable Suit (E-TeCS). We introduce a new platform of modular, conformable (i.e., flexible and stretchable) distributed sensor networks that can be embedded into digitally-knit textiles. This platform can be customized for various forms, sizes and functions using standard, accessible and high-throughput textile manufacturing and garment patterning techniques. We have developed a tailored, electronic textile conformable suit (E-TeCS) to perform large-scale, multi-modal physiological (temperature, heart rate, and respiration) sensing in vivo. Conformable Decoders. Youtube April 23, 2020 |

Also see

The Embroidered Computer Irene Posch

This gorgeous golden tapestry is actually a functional computer Fast Company

Clothes that communicate Ohio State University

An elastic fiber set to revolutionize smart clothes École polytechnique fédérale de Lausanne (EPFL)